Structurally the part that reduces warping of the board & socket from HSF pressure is the HSF's steel backplate. The CPU clamp is only there to apply slightly more pressure than is required to stop the CPU from falling out

With the frame in contact with the board, it's absolutely going to contribute to the board's ability to resist flexing. The IHS also barely protrudes from the top, so once you reach pressure enough to cause the lid to sit flush, it's very difficult (and mostly futile) to apply more.

Most backplates, including the Intel OEM ones, aren't anywhere near as rigid as I'd like. Intel's are much thicker and stiffer than the ones included with most AMD boards though.

A ZIF PGA socket gives a stable platform that HSF pressure can be applied to, independent of CPU pin connection pressure (which is applied sideways to the CPU pins).

It is perfectly possible to bend an ZIF PGA socket (they are plastic, and not all that thick), like AM4, sufficiently to cause problems, just by mounting some coolers. The boxed cooler that came with my 3900X will warp a cheap 4-layer board with the default backplate by about 3mm when locked down, which is enough to make the corners of the socket visibly higher than the center. I've had this cause issues with CPUs, or memory channels, being detected. I have other coolers, like my Thermalright IB-E Extreme, that have almost twice the mounting pressure of the boxed cooler's clamp. Fortunately, Thermalright provides a much thicker and very stiff backplate, so even with ~200 pounds of mounting pressure, the boards barely flex.

ETA done some googling on this, the LGA socket style (with the pins in the socket) allows for higher pin density, which seems like something that will become increasingly important as CPU technology progresses. Hopefully next time I need an upgrade a better solution will have been developed

Yes, the main reason for switching from PGA or micro PGA to LGA was electrical. There are fans of both packaging types, but I doubt consumer convenience is a major priority for AMD or Intel either way...most CPU sales aren't to end-users.

The price and performance differences between an Aston Martin Vantage and a Hyundai Santro are quite large. Both will get your kids to school. Both will get you to the grocery store. Both can take you on a weekend trip. However, the Vantage, being ten+ times the cost, offers significantly better performance and ride. You pay for the extra build quality, top grade components and a heck of a lot of research and development. You are not obliged to pay for a Vantage in any way. You are free to buy whatever vehicle fits your budget and needs, but your experience in a Santro on an eight hour road trip will be far inferior to one in a Vantage.

Thermal Grizzly works a treat. It is expensive when you compare it to others, but when you see the benefits of using quality paste and can run your CPU 2-6 Celcius cooler than someone using Ed's Bargain Basement brand from the Pound Shop, it's worth the cost. That's extra overhead my system can use for years. TG names a price and people pay it or not. That's the open market. Some recognize that quality costs a little more, but pays out dividends over time. Others buy the cheap stuff and moan about their "crap PC" overheating when idle.

I've used TG Kryonaut exclusively in my last three PC builds and plan to use it in my new 5975wx Threadripper PRO build. I've never had a second of regret. If you put together a £2,000+ PC, don't nickel and dime yourself with cheap paste.

We're not talking about the difference between some generic zinc oxide paste formulated forty years ago as a sunscreen and TG Kyronaut, but the difference between a dozen or so modern pastes with extremely similar properties.

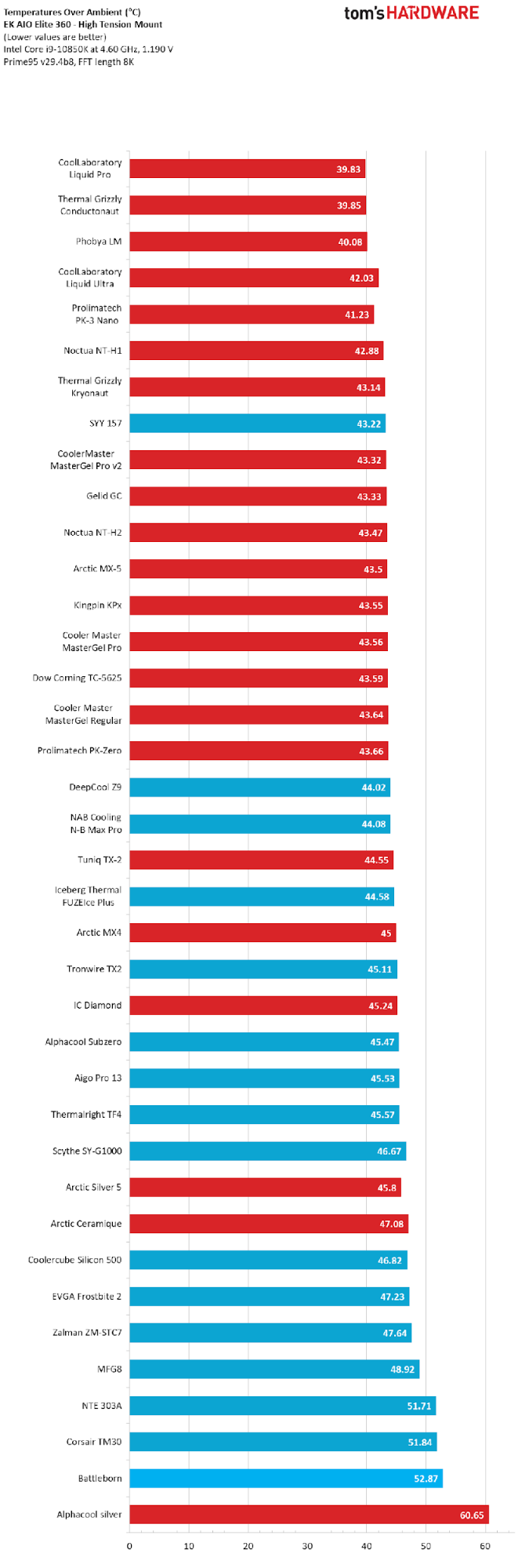

Among modern high-end pastes, I've used TG Kyronaut, Thermalright TFX, Noctua NT-H1/2, Arctic MX-4, Prolimatek PK-3, Cooler Master Mastergel Maker, SYY 157, and a few others. You'd be hard pressed to tell any of them apart in performance, especially the short term.

Raw performance is not the only factor either. NT-H2, for example, performs very well, but tends to flake off into tiny solid chunks when wiped away without using a solvent, which makes it annoying to remove. Likewise, TG Kyronaut and all the Prolimatek pastes use metallic aluminum fillers, and if you strip away the binder (while trying to clean it with solvents), you have ultra fine aluminum dust coating everything it was touching. I once killed one of my favorite X58 boards when I couldn't completely remove some stray PK-1 from the socket area. Also, some TIMs aren't viscous enough to last in the long term; the first incarnation of Thermalright Chill Factor performed extremely well on lapped surfaces, but lasted barely six months of heavy use due to pump out. Conversely, there are a few pastes that are so viscous that heatsink mounting pressure alone cannot achieve optimum bond line, or that require extensive thermal cycling to reach final performance. Some Shin-Etsu pastes were examples of this; they had the viscosity of wax and needed the container to be set in near boiling water or the component it was used on to be run without a fan, to get the TIM thin enough for it to perform right.

I want a TIM that perfoms well, lasts forever, cleans up easily, doesn't mandate special procedures to properly apply, and costs as little as practical.

Kyronaut's viscosity is a little on the low side, and, while it's rarely an issue, I don't like metallic fillers in conventional pastes. They also try to charge 30 dollars a cubic centimeter for it, unless you buy it by the tub.

My current go to paste is SYY-157, which is easily within 1C of Kyronaut, and thus far seems like it will last forever...it's also significantly less expensive than most of it's competitors. No metallic components to SYY 157 either.

For liquid metal TIMs, I've tried all the ones on Tom's chart and settled on Phobya, because it's the cheapest and doesn't really perform any worse than anything else. However, I only use liquid metal between bare silicon dies and nickel plated cold plates, which in practice, means it's currently on one of my video cards and nothing else. Gallium based TIMs alloy with bare copper, making it only last 6-18 months (if you want best performance), unless you carefully treat the surface before hand. Since I lap everything that's convenient to lap, it means everything that has a heat spreader/lid and all my CPU coolers/waterblocks wind up bare copper, even if they didn't come that way. Only GPU coolers keep their nickel plated bases because it's too much work to lap most of them while actually improving flatness.

Anyway, I don't have any regrets about the Kyronaut I've used either, but there are TIMs I consider to be superior, and among those there are at least a half-dozen that are close enough to be fungible.

Some things are worth spending just a little bit more on.

And sometimes you can get something just as good, or better, for a lot less.

Few of TG's products are outright bad (though their Minus Pad 8 came close), but almost all of them have an alternative that is within margin of error for significantly less. About the only thing I'd recommend TG for is their de-lid tools...though those might not even be TG branded, I think they are just Der8auer.

For the record, this is the most recent Tom's Hardware TIM performance chart for high mounting pressure with a cooler with a more or less flat base:

For the whopping 0.08C difference tested (which is way below margin of error) between Kyronaut and SYY 157, I am always going to pick the higher viscosity, completely non-metallic, TIM.

Edit: The newer Kyronaut Extreme (which I haven't tried myself) apparently has no metallic aluminum, only oxides, but I'm pretty sure the original Kyronaut is using metallic aluminum particles.