You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hardware & Technical which flight sticks should i get? X-52 or X-52 pro?

- Thread starter Ghost1

- Start date

A fair amount of love on the forums, but it's a very difference price point. The T.16000M is probably about the same price point, but it's a lot less pretty and doesn't have a matched throttle.

BTW, anyone in the UK after the X52/X52 pro (or anything else) and having stock problems can, AFAIK, always use the German etc. Amazons. Something like 205 euros (~£162), with the X52 costing about £109.

BTW, anyone in the UK after the X52/X52 pro (or anything else) and having stock problems can, AFAIK, always use the German etc. Amazons. Something like 205 euros (~£162), with the X52 costing about £109.

I really does hurt my soul, to see people settle for second hand crap like Saitek.

standards have fallen to the point where people accept what ever is tossed to them because it "Looks good"

if you are gonna spend money on a HOTAS.. then at least get something decent... hell get a Warthog is your pride demands it... that's the minimum I would allow for...

if you want quality and durability along with accuracy , then get a CH HOTAS

standards have fallen to the point where people accept what ever is tossed to them because it "Looks good"

if you are gonna spend money on a HOTAS.. then at least get something decent... hell get a Warthog is your pride demands it... that's the minimum I would allow for...

if you want quality and durability along with accuracy , then get a CH HOTAS

I got an X52 Pro on craigslist. Dewd, it's awesome. Perfect for ED. It would be even better if they would have stuff mappable to the rollers and sliders.

Yah agreed 100%. I put in a request to have things like left-centre-right view and scanner range have axis mappings as well as buttons in the feature requests forum...the more noise we get about it the more likely it'll happen.

Lestat

Banned

Well I have the x52 classic. When I look at it at the Garage sale. The only complaint I had was the stick part was lose. But a little common Sense you find a Youtube video Saitek x52 Spring Tension Mod Then I walk back to the Garage sale and payed for Saitek x52 $20. Then found a rubber washer and added it to the stick and it work great. Then that night I gave my old stick to my nephew.

No love then for the significant ly cheaper Thrustmaster?

I had one for years... would still be using it if it hadn't died while in storage. Of course they're not as accurate as the more expensive controllers, don't have as many buttons etc... no flashy lights or screens etc but they're still a lot better than a mouse & keyboard at an easy price point.

X52 is a great stick. If you get one used the magnet mod makes it even better since the stick is nonlinear to begin with. The mod makes it linear and more precise.

I bought mine used for $40 and after 6 months of use. If it broke I wouldn't be too upset if I had to buy another one for around $100.

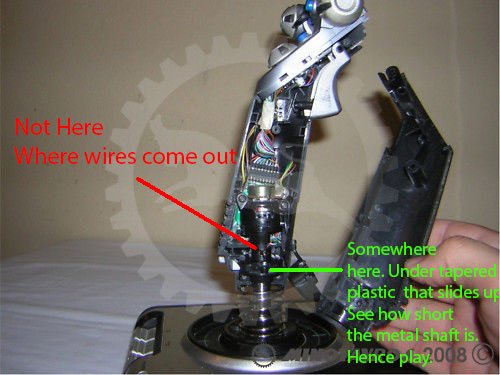

Internal construction isn't the best. If you ever do have to open it, it's well worth adding some protection where the wires come out the bottom of the metal stick shaft. The wires are less than 2mm thick and rub on the edge of the tube eventually some will break.

My used stick must have been a pretty old one that didn't get much use. I think there are a lot of them around if you check ads frequently. It's getting a bargain that is a bit more tricky.

I recently took mine apart and superglued the area where the shaft joins the handle. It only enters the handle about 1 inch. Metal tube over plastic with a 2mm metal pin. You do get a little extra play over time which is nice to have removed.

I bought mine used for $40 and after 6 months of use. If it broke I wouldn't be too upset if I had to buy another one for around $100.

Internal construction isn't the best. If you ever do have to open it, it's well worth adding some protection where the wires come out the bottom of the metal stick shaft. The wires are less than 2mm thick and rub on the edge of the tube eventually some will break.

My used stick must have been a pretty old one that didn't get much use. I think there are a lot of them around if you check ads frequently. It's getting a bargain that is a bit more tricky.

I recently took mine apart and superglued the area where the shaft joins the handle. It only enters the handle about 1 inch. Metal tube over plastic with a 2mm metal pin. You do get a little extra play over time which is nice to have removed.

Don't get x55 it's far worse than x52 pro (get it).

My X55 turned up a couple of days ago (from Overclockers here in the UK) and it's superb. None of the quality issues I've seen reported elsewhere and it seems really solidly made. Time will tell I guess, but so far so good.

Having got everything possible mapped to it I still have plenty of controls left over for the future and i've not had to use modes or shifting at all. The thing that really swung it for me over the X52 was the sheer number of HAT switches it has, especially the extra two on the throttle. The infinity scroller is also great for the sensor zoom as that can't be mapped to an axis yet.

I'm really looking forward to trying it out when my DK2 arrives - everything's easily reachable.

If you do fly anything else like DCS or FSX/Prepar3D then having the dual throttles is pretty useful too.

It is very expensive, but so far I have no buyer's remorse.

the x 52 (not pro is go too and less expensive). I found the binding interface a bit buggy though :s They actually used X52 (non pro version) at E3 2014

I recently took mine apart and superglued the area where the shaft joins the handle. It only enters the handle about 1 inch. Metal tube over plastic with a 2mm metal pin. You do get a little extra play over time which is nice to have removed.

How did you do this? How hard was it? Did you find a video showing how it's done or just went for ityourself?

I've got the same problem, play between the steel shaft and the plastic handle. It's my biggest problem with my now 9 year old X52.

How did you do this? How hard was it? Did you find a video showing how it's done or just went for ityourself?

I've got the same problem, play between the steel shaft and the plastic handle. It's my biggest problem with my now 9 year old X52.

I will see if I can find a pic of it with one side of the handle off. It's not that hard. There are 4x hex screws and about the same self tapping screws. The screw that holds the twist pot in place. then you can slide the pot and yaw lock mechanism up the shaft. You will see where the steel tube fits over the plastic part the shaft assembly sits. Just make sure you don't mistake the area you glue with the slot where the wires come out. That also has a pin to align the handle and take the pressure of the twist rudder.

The glue area is right where the metal shaft ends. Get some super glue, preferably the type that dries a little slower so you can wiggle the shaft and let the glue seep into the crack. hold it for half a minute. Put it all back together again.

That and the magnet mod and it will be better than a new X52 pro, let alone the old x52. The weak spring doesn't seem that bad after because there is no play in the top of the handle. You need the firmer spring normally to push against the handle and hide the play more than anything else.

If I find a good pic I will post it. I did take one because the pot assembly is a little confusing once removed.

Oh, and the glue doesn't effect the twist rudder which happens further up near where the wires come out.

The hardest part of disassemble is the big trigger guard and the pinkie trigger.

And just make sure the main trigger is pressed in slightly when you push the halves of the handle together since it will prevent the two halves closing.

It sounds more complicated above than it really is. But is still a little fiddly.

Found a pic that showed enough to give a approximate idea.

Last edited:

A quick FYI: those looking for UK stock of the X52 the Pro is due in at Scan Computers on the 9th of July while the standard X52 is due in on the 14th of July, just in time for the standard beta

Scan are getting 23 in supposedly tomorrow and 22 were taken by back orders, I got the 23rd. Over clockers are getting 30 in and they are all taken by back orders.

I just need to hope that they are supplied in full.

Scan are getting 23 in supposedly tomorrow and 22 were taken by back orders, I got the 23rd. Over clockers are getting 30 in and they are all taken by back orders.

I just need to hope that they are supplied in full.

amen to that, now that the SB backers have the Alpha 1 combat build i'm kind of wishing i'd ordered a pro instead of a standard just so i dont have to wait an extra week! but by the looks of it if i had i'd of missed out anyway

Scan are getting 23 in supposedly tomorrow and 22 were taken by back orders, I got the 23rd. Over clockers are getting 30 in and they are all taken by back orders.

I just need to hope that they are supplied in full.

My Scan order has been put back to the 18.07