Cheers Ven. I'm not your typical mobile phone type person either - just have it for work really. It's a scourge of modern life as far as I'm concerned - you hit on something with that remark and I feel quite passionate about it!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Community Event / Creation The C-Pod: A DIY Command seat (build log)

- Thread starter ThereIs0nly0ne

- Start date

Cheers Ven. I'm not your typical mobile phone type person either - just have it for work really. It's a scourge of modern life as far as I'm concerned - you hit on something with that remark and I feel quite passionate about it!

Crikey! Youre the first person I have ever heard of who has the same dislike of them...You know one of the most annoying things? It's when youre talking to someone about something important,their phone goes off,and they then answer it halfway through your conversation as if it's got to be the most important thing in the world! even if it's just their wife asking them to bring some milk home...very,very annoying indeed!

Crikey! Youre the first person I have ever heard of who has the same dislike of them...You know one of the most annoying things? It's when youre talking to someone about something important,their phone goes off,and they then answer it halfway through your conversation as if it's got to be the most important thing in the world! even if it's just their wife asking them to bring some milk home...very,very annoying indeed!

Haha. while true .. that mobile phones are good only for work and the ladies .. in the year 3300AD they'll probably be surgically implanted at birth .. plus the ROCCAT looks a very clever little app to me .. presumably you wouldn't even need a SIM card in the new fangled thngymajigwotsit ... ?

edit: ONE to watch!/

If the phone is nice and cheap, presume you could design your own ROCCAT UI, have one each side, pluse a live one to answer real life (work) calls without leaving your sidewinder !!

Last edited:

just speachless...this is awesome!!!

just speachless...this is awesome!!!

Thanks for that StevBrennan, it's appreciated

Lack of tangible progress can be a frustration. Limited time again this weekend but I have rethought the seat and pad structure a little and am intending to do some modifications. Hopefully I will complete these tomorrow - depending on my back situation

Next weekend will see me back in full swing when I will be tackling the seat sides. I will also consider how to mount to a base and what that should look and function like.

Additionally, I consider the encased throttle unnecessarily heavy - I'll be removing the two lower plates and associated weights from the underside and look to mount that into the case.

The reason I hate mobiles is actually due to work. The tipping point was when I was contacted by work to look into a critical production service issue. 36 hours later, complete with blistered ears due to my headset breaking, I put the phone down ... followed swiftly by another 60+ hours of calls for the remainder of the week. Only bananas and coffee were harmed in the making of that week.

Thanks for that StevBrennan, it's appreciated

Lack of tangible progress can be a frustration. Limited time again this weekend but I have rethought the seat and pad structure a little and am intending to do some modifications. Hopefully I will complete these tomorrow - depending on my back situation

Next weekend will see me back in full swing when I will be tackling the seat sides. I will also consider how to mount to a base and what that should look and function like.

Additionally, I consider the encased throttle unnecessarily heavy - I'll be removing the two lower plates and associated weights from the underside and look to mount that into the case.

The reason I hate mobiles is actually due to work. The tipping point was when I was contacted by work to look into a critical production service issue. 36 hours later, complete with blistered ears due to my headset breaking, I put the phone down ... followed swiftly by another 60+ hours of calls for the remainder of the week. Only bananas and coffee were harmed in the making of that week.

Looking forward to see progress on the seat! And interesting with the changes, but why would you ever want to take that beautiful throttle casing apart!?

Weight, I undertand that, but when mounted it doesnt really matter does it?

Besides, weight good, weight is a sign of relybillity!

Looking forward to see progress on the seat! And interesting with the changes, but why would you ever want to take that beautiful throttle casing apart!?

Weight, I undertand that, but when mounted it doesnt really matter does it?

Besides, weight good, weight is a sign of relybillity!

Weight is generally good

The full case weighs a few kg now and needs to lose some fat! It'll be more than substantial enough without the plates. The stick case on the other hand (without the metal base plate) seems about right.

Weight is generally goodToo much weight could make things unnecessarily challenging when it comes to positioning these on the mounting poles - particularly if I need to offset slightly from centre. I'm also considering a thin platform to wrap around the tops of the poles for extra stability. These will need to be epoxy'd onto the poles.

The full case weighs a few kg now and needs to lose some fat! It'll be more than substantial enough without the plates. The stick case on the other hand (without the metal base plate) seems about right.

Alrite mate, well you know best! Weight and feel is hard to grasp over pictures and text

Looking forward to tomorrow then!

Spectre Alpha

Banned

Take a cue from the modern fighters glass cockpit and go with touchscreens instead of buttons and switches, much more elegant solution and can be remapped at will and for various user setups.

Take a cue from the modern fighters glass cockpit and go with touchscreens instead of buttons and switches, much more elegant solution and can be remapped at will and for various user setups.

Yup, an iPad mini on the stow-able centre console will be the preferred option. I also need to consider mouse type controls (which could be done with a tablet) as well. The idea will be to make the console flexible enough to accommodate different types of devices - For flexibility, I'll need to run several different types of cables to the platform the devices will sit on. I have some ideas on how best to handle the cabling and will see if they work out.

Spectre Alpha

Banned

Yup, an iPad mini on the stow-able centre console will be the preferred option. I also need to consider mouse type controls (which could be done with a tablet) as well. The idea will be to make the console flexible enough to accommodate different types of devices - For flexibility, I'll need to run several different types of cables to the platform the devices will sit on. I have some ideas on how best to handle the cabling and will see if they work out.

No, too small, A tablet built into a recessed area would be better. And a full sized one, not one of those little kiddie screens.

No, too small, A tablet built into a recessed area would be better. And a full sized one, not one of those little kiddie screens.

But my wife only has an iPad mini

Rafe Zetter

Banned

Weight is generally goodToo much weight could make things unnecessarily challenging when it comes to positioning these on the mounting poles - particularly if I need to offset slightly from centre. I'm also considering a thin platform to wrap around the tops of the poles for extra stability. These will need to be epoxy'd onto the poles.

The full case weighs a few kg now and needs to lose some fat! It'll be more than substantial enough without the plates. The stick case on the other hand (without the metal base plate) seems about right.

Do you have the ability to route away some of the fat from the interior of the panels? It's quite likely that you could thin out sections halfway or 2/3rds without losing any integrity. If you knew which side was going to overhang more, like the right hand (outer) side of the joystick case, you could thin that down more, and the left side (inside) section less to move the centre of balance.

For the thin platforms, I would personally run a thin bar all the way through the tube and have the platform sit on that (even a section of wire coathanger will work), as well as the epoxy, that way the bar will take the weight more and rely less on the epoxy simply clinging onto the side of a smooth vertical bar. While it's adhesive qualities are good, it only goes so far on smooth surfaces, any tension in the wrong direction and the while joint will fail at once.

You might also consider ramming a large wooden dowel down into the first few inches - wood broom handles are good, but match it to the tube first, then put a screw or two into the tube where the wood is. Screw / glue the thin platform on top to the wood and voila, not going anywhere.

With the wood dowel system you can also add a collar to the pole to increase the surface support area; block of wood, drill hole to match tube, slide onto tube then screw block to the wood inside tube.

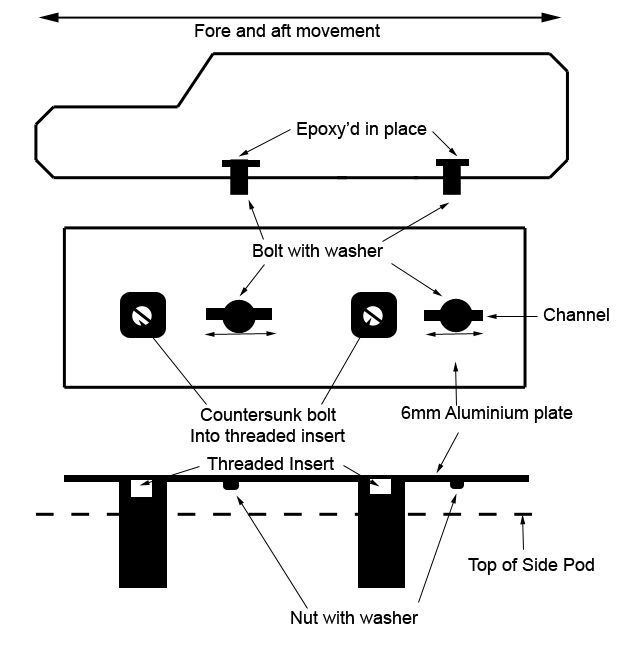

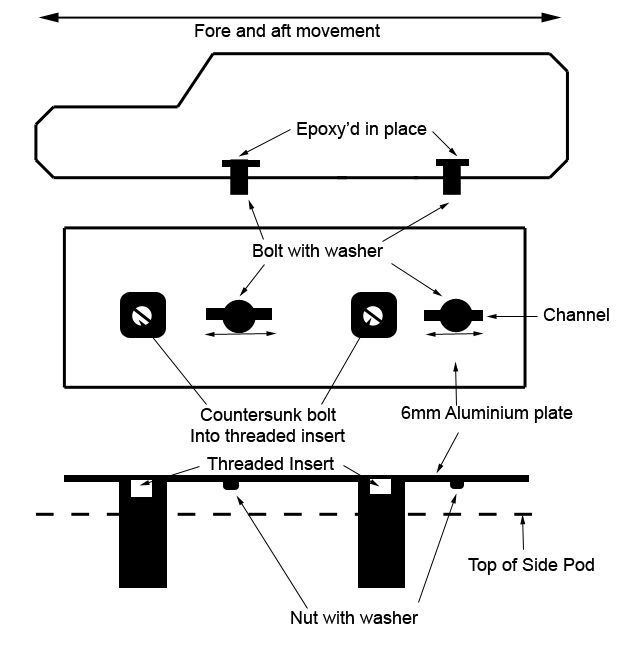

Thanks for your input Ven. The bottom plates of the throttle are much heavier than any MDF I would be able to route away. I want to leave the cases themselves intact as much as possible. The only thing I'm intending to do is to drill a couple of holes for attachment purposes. This is the design I have in mind at present.

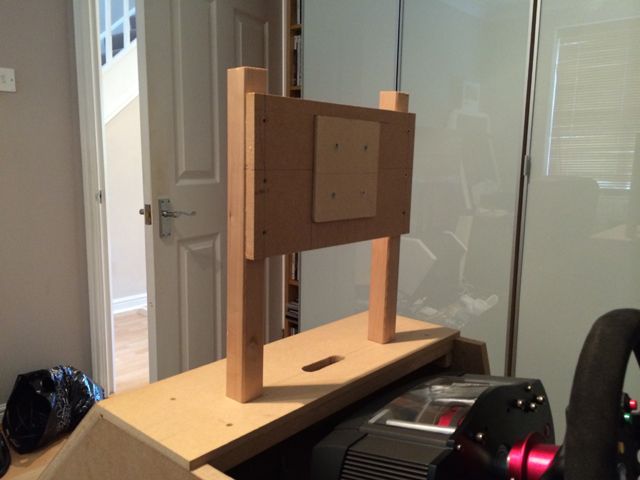

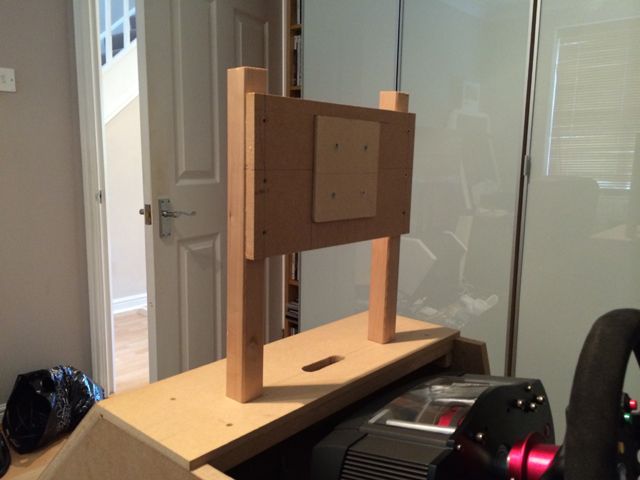

I will purchase 2 x 6mm (but possible 5/4mm) plates for the top of the supporting poles. The poles are to be made from hardwood. I used this on my monitor mount for my rig and it's very sturdy:

The plan is to drill 2 holes into the bottom of each case. I will pass a bolt through each of these and use a washer also, These will be epoxy'd in place to prevent any movement.

I will drill a hole into each of the supporting poles which will be embedded into the pods located at the side of each seat. Each hole will have a threaded insert screwed into place.

The aluminium plate will be attached to each pair of poles using coutersunk bolts.

Each plate will have 2 channels cut into it.

The bolts extending from the underside of each of the cases will pass through the channels and will be bolted in place from the underside.

The channels will allow a degree of fore and aft movement.

This is the design:

Edit: The channels or counter sunk bolts may be off-centre depending on what it is like getting into and out of the seat - I don't want to inadvertently catch them getting in and out.

Edit 2: it may be possible to use only one channel between the poles and pass both attaching bolts through it. The basic principles remain the same.

I will purchase 2 x 6mm (but possible 5/4mm) plates for the top of the supporting poles. The poles are to be made from hardwood. I used this on my monitor mount for my rig and it's very sturdy:

The plan is to drill 2 holes into the bottom of each case. I will pass a bolt through each of these and use a washer also, These will be epoxy'd in place to prevent any movement.

I will drill a hole into each of the supporting poles which will be embedded into the pods located at the side of each seat. Each hole will have a threaded insert screwed into place.

The aluminium plate will be attached to each pair of poles using coutersunk bolts.

Each plate will have 2 channels cut into it.

The bolts extending from the underside of each of the cases will pass through the channels and will be bolted in place from the underside.

The channels will allow a degree of fore and aft movement.

This is the design:

Edit: The channels or counter sunk bolts may be off-centre depending on what it is like getting into and out of the seat - I don't want to inadvertently catch them getting in and out.

Edit 2: it may be possible to use only one channel between the poles and pass both attaching bolts through it. The basic principles remain the same.

Last edited:

But my wife only has an iPad mini

Not anymore she doesn't !!! ;D

Excellent .. it looks like a new phase starting, stand for the screen coming on? Sweet.

Not anymore she doesn't !!! ;D

Excellent .. it looks like a new phase starting, stand for the screen coming on? Sweet.

I'm sure she won't notice

I wish I was that far advanced Winterwalker. Just remodeling the seat shape as we speak.

Thanks for your input Ven. The bottom plates of the throttle are much heavier than any MDF I would be able to route away. I want to leave the cases themselves intact as much as possible. The only thing I'm intending to do is to drill a couple of holes for attachment purposes. This is the design I have in mind at present.

I will purchase 2 x 6mm (but possible 5/4mm) plates for the top of the supporting poles. The poles are to be made from hardwood. I used this on my monitor mount for my rig and it's very sturdy:

The plan is to drill 2 holes into the bottom of each case. I will pass a bolt through each of these and use a washer also, These will be epoxy'd in place to prevent any movement.

I will drill a hole into each of the supporting poles which will be embedded into the pods located at the side of each seat. Each hole will have a threaded insert screwed into place.

The aluminium plate will be attached to each pair of poles using coutersunk bolts.

Each plate will have 2 channels cut into it.

The bolts extending from the underside of each of the cases will pass through the channels and will be bolted in place from the underside.

The channels will allow a degree of fore and aft movement.

This is the design:

Edit: The channels or counter sunk bolts may be off-centre depending on what it is like getting into and out of the seat - I don't want to inadvertently catch them getting in and out.

Edit 2: it may be possible to use only one channel between the poles and pass both attaching bolts through it. The basic principles remain the same.

Will you need to remove the cases every time u enter/exit the seat and is this done through the nuts on the underside? Wont this be a hassle for you?

You mentioned something about strong neodym magnets, was that for something else?

No need to remove the cases each time; that's a very important factor and is what the offset is for - I don't want these to interfere/catch me with getting in and out.The offset will likely be around 3cm by my rough calculations. This will ensure that the sides of the cases are flush with the inside panels of the seat. It also dictates the need for a strong platform, hence the use of an aluminium panel. That's also the reason for losing the weight of the pods - unnecessary strain on the platform is removed. Solidity is my number one target in all projects.

I have re-cut the sides for the seat sub-frame. On closer inspection of my bucket seat, I can see there is a change in the rake angle at the back of the seat around the mid point between the seat base and shoulder area. Hopefully this will be a close match. I'll know soon when I assemble. After extensive sitting and testing I've also dropped the back of the base by 2.5 cm so I lean back a little further. This seems to be the best/most comfortable seat position for me. There is no change between the seat base and lower back section.

I have re-cut the sides for the seat sub-frame. On closer inspection of my bucket seat, I can see there is a change in the rake angle at the back of the seat around the mid point between the seat base and shoulder area. Hopefully this will be a close match. I'll know soon when I assemble. After extensive sitting and testing I've also dropped the back of the base by 2.5 cm so I lean back a little further. This seems to be the best/most comfortable seat position for me. There is no change between the seat base and lower back section.